KeyMission is Nikon's action cam product line.

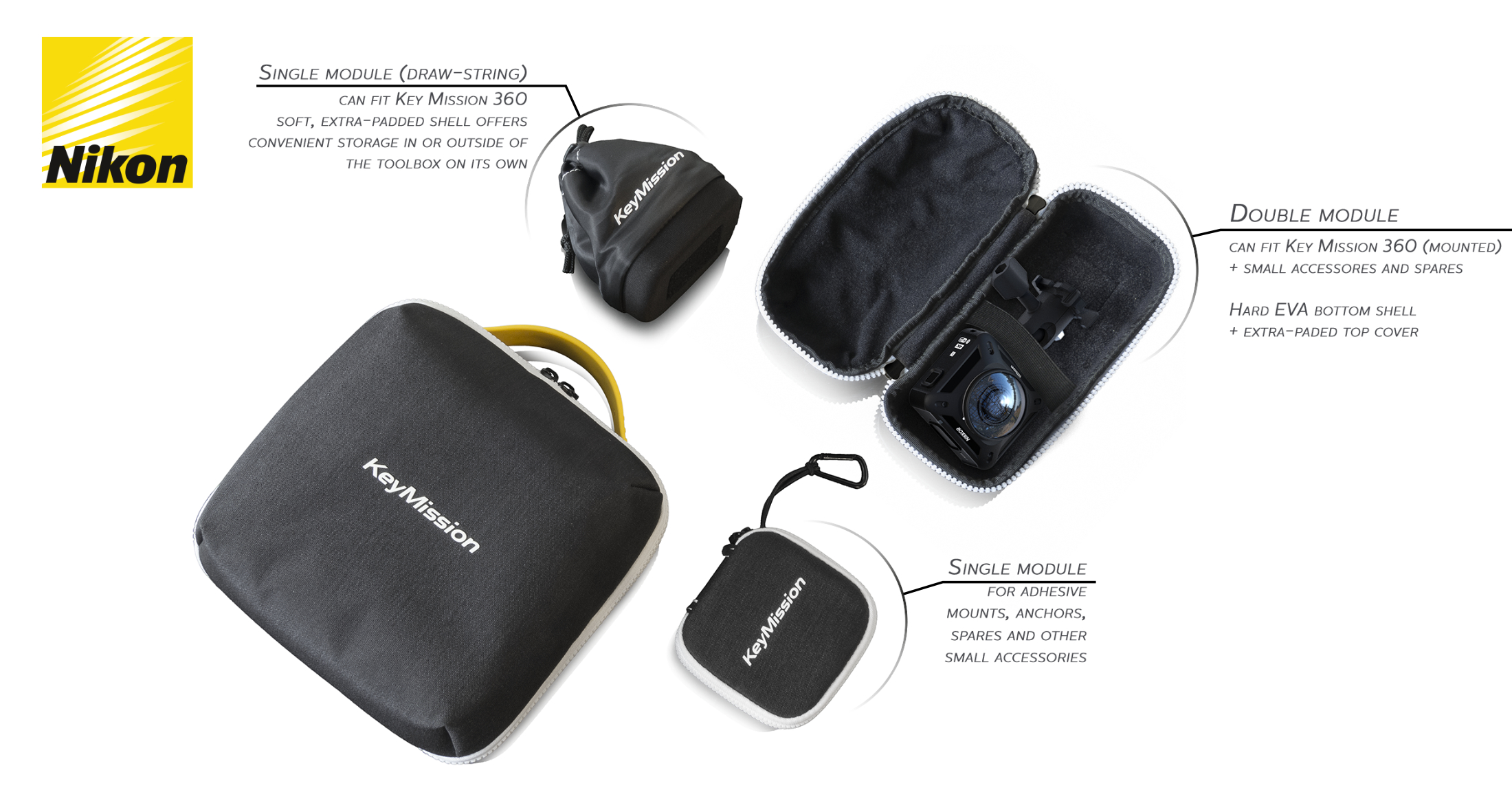

To address a wide variety of usage scenarios which are typical of action camera ecosystems, modular design was employed. That way a user can configure a kit according to his or her gear type and assortment. Users can be geared towards watersports, for instance, or towards rock climbing, just as well. Configuration flexibility also meant future-proofing as often the accessory range would grow over time or certain activities would require less gear than others.

Replaceable bag-in-bag modules with varying design according to function and purpose. The name Toolbox illustrates the idea quite well. A master case, much like a toolbox, carries equipment some of which may be used differently depending on the day.

A digital sketch set the general direction and then straight into MoI3D for 3D models which were exported as meshes, brought into Octane Render, lit and textured and approved following several iterations.

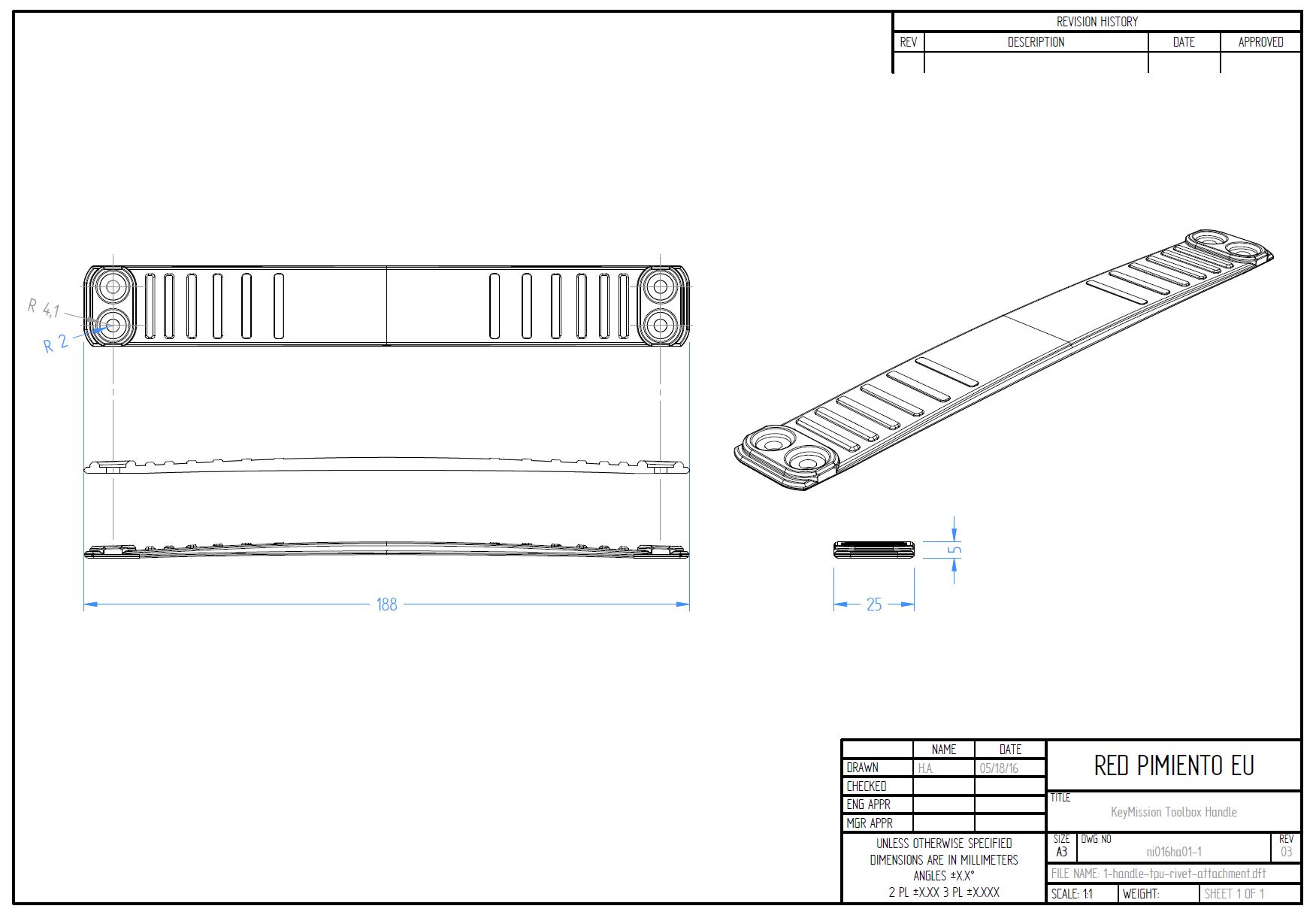

Then, CAD models of the EVA treys were refined for production in cooperation with the factory. The handle was optimized for injection moulding and became the second-ever injected piece in my portfolio.

Material selection, final cost estimation and sample rounds followed before start of production for delivery.